Understanding the Difference Between Mechanical Shoe and Liquid Mounted Seals: A Guide to 40 CFR 60 Kc Compliance

In the world of tank storage, compliance with environmental regulations is critical. One such regulation, 40 CFR 60 Kc, issued by the U.S. Environmental Protection Agency (EPA), which mandates the use of specific seals to minimize emissions from storage tanks, particularly volatile organic compounds (VOCs).

The two primary types of seals—mechanical shoe and liquid-mounted seals—play a pivotal role in ensuring compliance. While both types of seals serve to reduce VOC emissions, the EPA has distinct criteria for each under 40 CFR 60 Kc. Here’s what you need to know about these two seal types and why it matters for tank owners and operators.

The Basics of Mechanical Shoe Seals and Liquid Mounted Seals

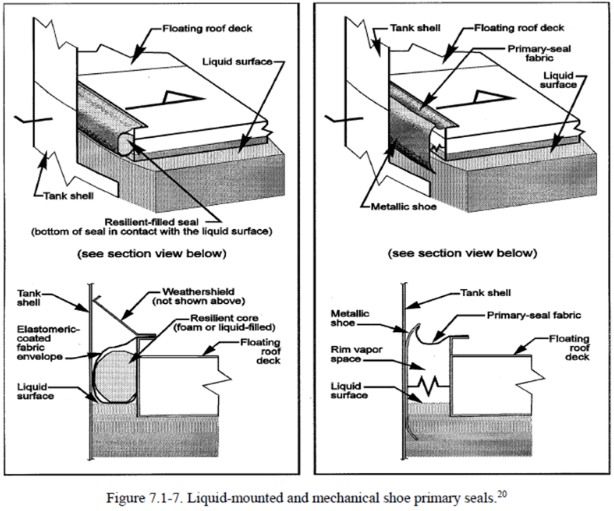

- Mechanical Shoe Seals: These seals consist of a metal band or “shoe” that rests against the tank wall. A key characteristic of this design is that it creates a vapor space between the seal and the liquid, allowing some vapors to escape into the atmosphere. While mechanical shoe seals are often used in tank storage, they do not provide the same level of emission control as liquid-mounted seals.

- Liquid Mounted Seals: In contrast, liquid-mounted seals sit directly on the liquid surface inside the tank, forming a continuous barrier. This design eliminates more of the vapor space between the seal and the liquid, effectively minimizing the opportunity for vapors to escape into the air. Liquid-mounted seals are considered a more effective solution for VOC emission control and are able to meet 40 CFR 60 Kc compliance.

The figure below is from the EPA and shows their differentiation between a liquid-mounted seal (on the left) and a mechanical shoe seal (on the right).

40 CFR 60 Kc and the EPA’s Requirements

Under 40 CFR 60 Kc, the EPA has made it clear that liquid-mounted seals offer superior emission control and are the preferred technology for certain storage tanks. The regulation mandates that tanks meeting specific size and emission criteria (of which a vast majority of ASTs meet) must use liquid-mounted seals as a way to limit VOC emissions and ensure that storage tanks do not contribute to air pollution.

The EPA’s differentiation between the two seal types is based primarily on the effectiveness in reducing emissions. Because liquid-mounted seals form a tighter seal with the liquid surface, they prevent vapor leakage more effectively than mechanical shoe seals, making them the regulatory standard for certain applications.

Why Does This Matter?

For tank owners and operators, understanding the difference between mechanical shoe and liquid-mounted seals is crucial for compliance with EPA regulations. Failing to use the required seal type could lead to:

- Non-compliance penalties: Not meeting the EPA’s 40 CFR 60 Kc requirements can result in hefty fines and legal consequences.

- Increased emissions: Using less effective seals may lead to higher VOC emissions, contributing to environmental damage, potential public health risks, and damage to your reputation.

- Operational inefficiency: Tanks that don’t meet regulatory standards might face more frequent inspections, maintenance needs, and potential shutdowns, affecting productivity and profitability.

Mesa ETP’s Role in Compliance

At Mesa Engineered Tank Products, we understand the importance of meeting 40 CFR 60 Kc compliance. Our solutions, including FlexCore™ the best-in-industry liquid-mounted seal, are designed to help tank owners and operators stay compliant with EPA standards while also optimizing their tank systems for greater efficiency and safety.

We provide a range of products custom engineered to meet the most stringent environmental standards, including liquid-mounted seals, leg boots, and wiper seals that help reduce emissions and keep your tanks compliant. Our solutions not only ensure compliance but also enhance operational performance, providing long-term durability and reliability for your tank systems.

Final Thoughts

Meeting 40 CFR 60 Kc compliance is an essential part of responsible tank operation and environmental stewardship. By understanding the critical differences between mechanical shoe seals and liquid-mounted seals, and using the appropriate technology, tank owners can ensure they are following EPA guidelines while minimizing their environmental impact.

If you’re looking for solutions to help with sealing your tanks to meet 40 CFR 60 Kc compliance, Mesa ETP is here to provide the expertise and products you need to succeed.

Check out our comprehensive articles on 40 CFR 60 Kc here! Make sure you also download our free 40 CFR 60 Kc compliance checklist!

Monthly Archives

- March 2025

- February 2025

- December 2024

- November 2024

- May 2024

- April 2024

- January 2024

- October 2023

- August 2023

- May 2023

- April 2023

- June 2022

- May 2022

- September 2021

- July 2021

- January 2021

- August 2020

- July 2020

- May 2020

- April 2019

- January 2019

- November 2017

- October 2017

- July 2017

- June 2017

- May 2017

- April 2017

- February 2017

- November 2016