40 CFR 60 Kc Compliance: What Tank Operators Need to Know

Staying compliant with environmental regulations like 40 CFR 60 Kc isn’t just about avoiding penalties—it’s about building sustainable operations that align with today’s industry standards.

Emissions compliance is becoming increasingly critical for industries that rely on storage tanks. One key regulation is 40 CFR 60 Kc, which governs emissions and operational standards for certain tanks to mitigate their environmental impact.

Let’s break down what 40 CFR 60 Kc compliance entails, why it matters, and how you can ensure your operations stay compliant.

What is 40 CFR 60 Kc?

40 CFR 60 Kc is a key section of the Clean Air Act that focuses on the emissions from volatile organic liquids (VOLs) stored in large tanks. This regulation sets stringent requirements to help minimize the release of harmful volatile organic compounds (VOCs), which are a major contributor to air pollution and smog formation. The main purpose of 40 CFR 60 Kc is to control emissions from tanks that store VOLs with a high potential for evaporation, ensuring that facilities comply with federal standards to reduce harmful environmental impacts.

Who Needs to Comply?

This regulation applies primarily to tank owners and contractors responsible for managing storage units that meet specific criteria, including size and the nature of the material being stored. This regulation targets large storage tanks, particularly those that handle VOLs like crude oil, gasoline, and other chemicals that can release VOC emissions into the atmosphere.

The regulation applies to tanks with a storage capacity of at least 75 cubic meters (approximately 19,813 gallons). Tanks that were constructed, reconstructed, or modified after October 4, 2023 will need to become compliant with these new regulations. This is a critical date for owners and operators to track, as it sets the timeline for when the regulations take effect for new or newly modified tanks.

The Main Goal

The overarching goal of 40 CFR 60 Kc is to regulate emissions from storage tanks by ensuring that volatile organic compounds are properly controlled. VOCs can contribute significantly to air pollution, including smog and ozone formation, which are harmful to our health and the environment. This regulation sets standards for:

- Controlling Emissions: It focuses on ensuring tanks have the proper seals, covers, and venting systems in place to prevent VOCs from escaping into the atmosphere.

- Seal Installation: Tanks must be equipped with specific sealing technologies, such as floating roofs or double-seal systems, to effectively reduce emissions.

- Minimizing VOC Release: By limiting VOC emission leakage, the EPA aims to reduce pollution and improve air quality.

For example, if you own a storage tank that handles volatile organic liquids, compliance means installing specific seals (e.g., floating roofs) and venting mechanisms to ensure that minimal VOC emissions are released. These measures help you meet emissions standards and contribute to a cleaner environment.

Key Requirements

1. Emissions Limits:

Tanks must adhere to strict emissions thresholds set by 40 CFR 60 Kc. The regulation introduces stricter emissions control efficiency requirements when compared to previous versions (Kb).

- Efficiency Requirement: 40 CFR 60 Kc compliance requires that tanks achieve 98% emissions control efficiency, which is an improvement over the 95% efficiency required under the earlier 40 CFR 60 Kb.

- Consequences for Exceeding Limits: If your tank exceeds the emissions limits, it can lead to significant fines and additional oversight from the EPA. The fines for each violation can be applied per day of non-compliance which can rapidly add up.

2. Seal Requirements:

The regulation sets standards for seals, guide poles, roof seals, and other fittings to ensure proper installation and performance to minimize leakage. These seals help prevent VOC emissions from leaking into the atmosphere, especially during tank filling and emptying.

- Floating Roof Requirement: Tanks must either have a floating roof(e.g., Mesa ETP’s new FlexCore system) or an equivalent emission control system. The floating roof provides a barrier between the liquid stored in the tank and the air above, reducing VOC emissions.

- Slotted Guide Pole Tanks: For tanks with a slotted guide pole, the primary seal must be either a liquid-mounted seal or a mechanical shoe seal, along with a rim-mounted secondary seal.

- Ban on Vapor-Mounted Primary Seals: Vapor-mounted primary seals, such as wedge or flapper styles, are no longer permitted under 40 CFR 60 Kc. These older seal types are less effective at controlling emissions, hence why they have been phased out in favor of more reliable and efficient technologies.

Double-seal systems combine a primary and secondary seal, offering better control over VOC emissions than older single-seal systems, making them a preferred solution under the new regulations.

3. Timeline:

40 CFR 60 Kc compliance is being phased in based on tank size and operational criteria. The regulation allows for varying timelines depending on the specifics of each tank’s operation.

- Vapor Pressure Requirements: Tanks storing liquids with a maximum true vapor pressure (TVP) of 0.25 psia or greater at standard conditions must meet the new emissions control system requirements.

- Mandated Deadlines: It is crucial for tank owners to ensure that modifications and operational updates are completed before the required deadlines. Failure to meet these deadlines may result in penalties and enforcement actions from regulatory agencies.

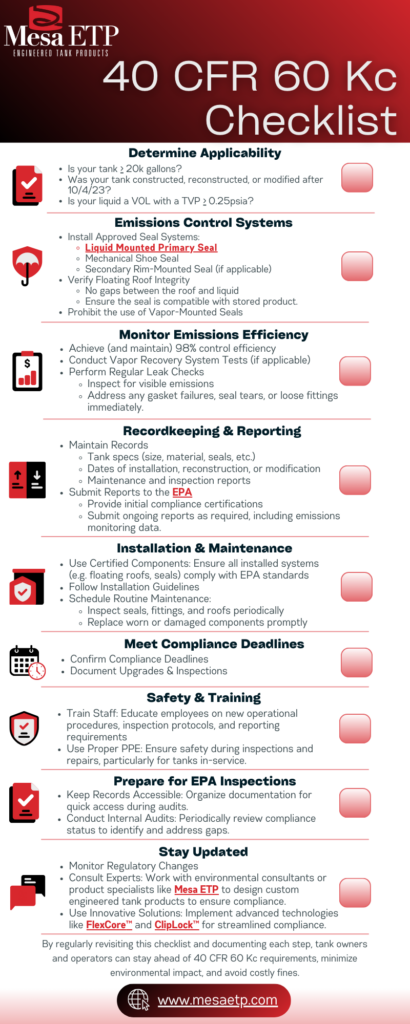

Pro Tip: Use our Compliance Checklist to track your progress in meeting these requirements.

Why Compliance Matters

Risks of Non-Compliance

Fines & Legal Issues: Non-compliance with regulatory standards like 40 CFR 60 Kc can result in significant financial penalties. The EPA enforces strict fines for violations, which can amount to staggering costs per violation, with penalties increasing for ongoing violations. These fines not only affect your bottom line but could also lead to lengthy legal battles, further increasing costs. Violations could also trigger additional enforcement actions, including criminal penalties for willful noncompliance, which may involve prison sentences for responsible individuals. The risk of legal disputes and the associated costs can significantly impact your business’s financial health and operations.

Operational Disruptions: Failing to meet emissions standards or maintain proper equipment can lead to operational delays or even forced shutdowns. If your facility is found to be in non-compliance, regulatory authorities may mandate a temporary halt in operations until corrective measures are implemented. This can lead to costly downtime and delays in production, which ultimately affect revenue. Additionally, retrofitting tanks or implementing corrective actions may require significant investments of time and resources, further impacting operational efficiency. Frequent compliance issues can result in periodic interruptions to your daily operations, reducing overall productivity.

Damage to Reputation: In today’s environmentally-conscious market, a company’s reputation is closely tied to its commitment to regulatory compliance and sustainability practices. Regulatory breaches can severely damage your brand’s public image, eroding trust with customers, investors, and other stakeholders. A damaged reputation often leads to reduced consumer confidence, which can impact sales and market share. Public exposure of non-compliance can have long-lasting effects, making it harder to regain the trust of your target audience, even after compliance is restored. The transparency and accountability demanded by environmental regulations also reflect on your overall corporate ethos, and any lapse can tarnish your reputation.

Benefits of Compliance

Improved Efficiency: Regularly updating seals, emission control systems, and monitoring equipment in line with these new regulations can improve the overall efficiency of your storage tanks and operational processes. For instance, the installation of more effective emission control systems, like floating roofs or vapor recovery units, can reduce losses, optimize storage capacity, and streamline tank operations. Properly maintained equipment often operates more smoothly, leading to fewer breakdowns and disruptions. In the long term, this efficiency not only supports regulatory compliance but also enhances overall system performance, helping businesses achieve a more predictable and streamlined production process.

Cost Savings: While initial compliance costs—such as retrofitting tanks, installing control devices, and performing regular inspections—can seem high, they can lead to significant long-term savings. By avoiding environmental fines, penalties, and potential litigation, companies can maintain a healthier financial position. Moreover, the efficiency improvements brought by maintaining updated emission control systems reduce operational waste, lower energy consumption, and extend the lifespan of equipment. This leads to fewer repair costs and greater system reliability, ultimately saving money over time. Also, investing in compliance can reduce insurance premiums, as businesses with a history of regulatory adherence are seen as lower-risk entities.

Environmental Responsibility: 40 CFR 60 Kc compliance reflects a company’s commitment to environmental stewardship and sustainability. By adhering to emissions standards, businesses reduce their environmental footprint and contribute to cleaner air and water. This commitment resonates strongly with consumers who prioritize sustainability when making purchasing decisions. Moreover, government agencies and stakeholders are increasingly holding companies accountable for their environmental practices, and compliance signals a proactive approach to minimizing negative environmental impacts. Companies with robust environmental practices are seen as leaders in the industry, creating opportunities to partner with other like-minded organizations and access green incentives or certifications.

Positive PR: Demonstrating compliance can significantly enhance a company’s public image. In a market where environmental awareness is on the rise, being recognized as a responsible and compliant company can boost customer loyalty, attract new customers, and even open the door for more profitable partnerships. Companies that actively promote their compliance efforts position themselves as leaders in corporate responsibility, which can be a powerful marketing tool. Publicly emphasizing sustainability and regulatory adherence can also differentiate your brand in a crowded market, making it more attractive to investors, consumers, and other key stakeholders who value ethical operations. By embracing compliance and transparency, you strengthen your reputation and gain an edge over competitors who may be less diligent in adhering to regulations.

Final Insights

Understanding 40 CFR 60 Kc compliance is essential for tank owners aiming to meet industry standards and reduce environmental harm. While the compliance process may seem daunting, it’s a necessary and rewarding step toward sustainable and efficient operations.

Ensuring compliance with environmental regulations like 40 CFR 60 Kc is not just about avoiding penalties—it’s an investment in your business’s long-term success. The cost savings, improved operational efficiency, and reputation benefits that come with adherence to environmental standards far outweigh the risks associated with non-compliance. Furthermore, the environmental responsibility that comes with maintaining compliance aligns your company with current sustainability trends, helping you build trust with consumers and investors alike. Ultimately, the benefits of compliance extend beyond regulatory requirements, positioning your business for future growth, profitability, and positive public recognition.

Take action today—equip yourself with the right tools and support to navigate compliance successfully.

Learn More: Visit the EPA’s official page on 40 CFR 60 Kc for full details.

Explore Your Options: Check out Mesa ETP’s FlexCore, ClipLock, other solutions to help you meet compliance standards effortlessly.

Monthly Archives

- March 2025

- February 2025

- December 2024

- November 2024

- May 2024

- April 2024

- January 2024

- October 2023

- August 2023

- May 2023

- April 2023

- June 2022

- May 2022

- September 2021

- July 2021

- January 2021

- August 2020

- July 2020

- May 2020

- April 2019

- January 2019

- November 2017

- October 2017

- July 2017

- June 2017

- May 2017

- April 2017

- February 2017

- November 2016